Laser Cutter Filtration System

LSR-04-0353

Couldn't load pickup availability

Pickup available at InkSmith Education

Usually ready in 2-4 daysPairs well with

Laser Cutter Filtration System

Product details

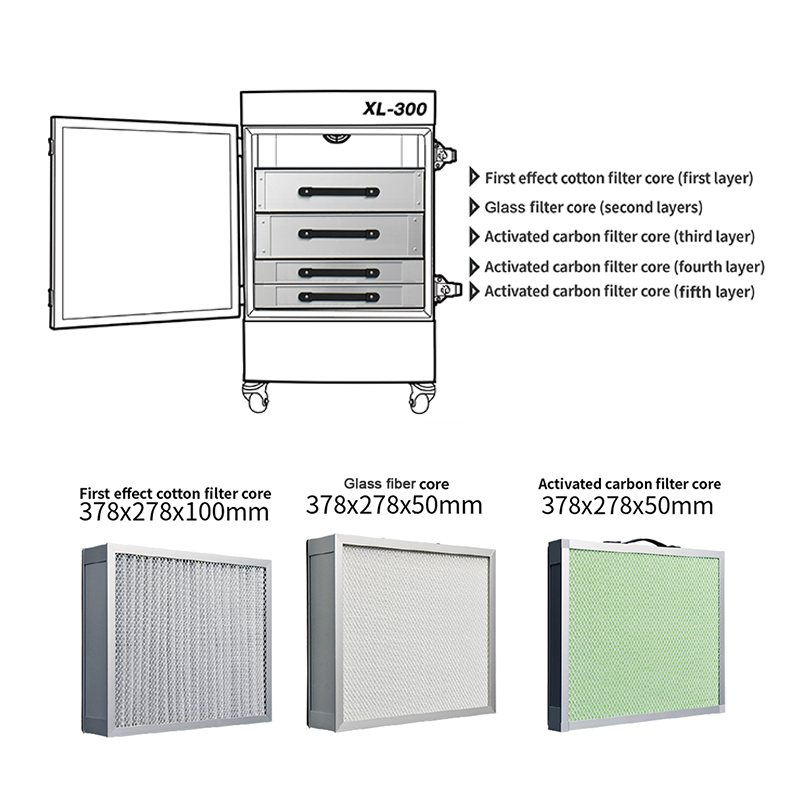

The XL-300 Filtration System is the ideal set-up for operating the Mako 60W Laser Cutter in a closed environment. The Filtration System consists of a 5-layer filter core to intercept airborne particles, absorb gases and odours, and purify air output. These layers consist of a cotton core, a glass filter core, and three activated carbon filter core layers.

The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. The modular internal layers make it easy to replace the filter cores once they have reached their lifespan.

The XL-300 filter cores should be replaced after approximately 60-80 hours of use, however, this is just a guideline. The lifespan of the filter cores will vary greatly depending on what material is being cut/engraved. We recommend checking the filters on a bi-weekly basis to monitor debris build-up.

Technical Specifications

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

Contact Us

Use this text to answer questions in as much detail as possible for your customers.